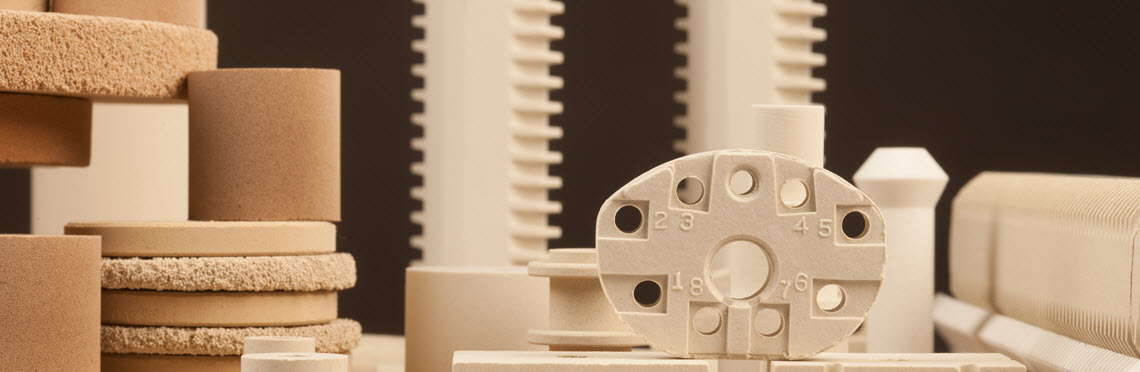

High-tech ceramics are ideal materials for components and industrial products due to their versatile properties: extraordinary hardness and resistance to wear, heat and corrosion, and — according to the individual material mix — excellent insulating and/or non-conductive properties.

For low-cost ceramic insulators, Maryland Ceramic & Steatite offers two basic materials:

L3 Steatite — Maryland Ceramic & Steatite’s steatite ceramic is ideal for high frequency, low loss, and high voltage insulation. Our L-3 Steatite has good mechanical properties and low loss electrical qualities. It is ideal for resistor forms, igniters, standoffs, surge arrestors, coil forms, spacers, spark plugs, etc. Steatite is easily fabricated to close tolerances and is much less expensive than alumina ceramic insulators.

Cordierite — Maryland Ceramic & Steatite’s cordierite has excellent thermal shock resistance, withstanding red heat to ice water quench, and then a return to red heat. Our high fire cordierite body will withstand a temperature rise from 70°F to 1800°F in 80 seconds, followed by an immediate room-temperature air quench.

Maryland Ceramic & Steatite offers a consistent even-grain ceramic structure possessing better density and particle size. Better body composition means less shrinkage and provides advantages in firing operations.

We would be pleased to submit quotations upon receipt of inquiries that should include drawings and the quantities required. Custom firing can be done at a nominal price.

Government designation: L312C

Manufacturer’s Designation: L-3 Steatite